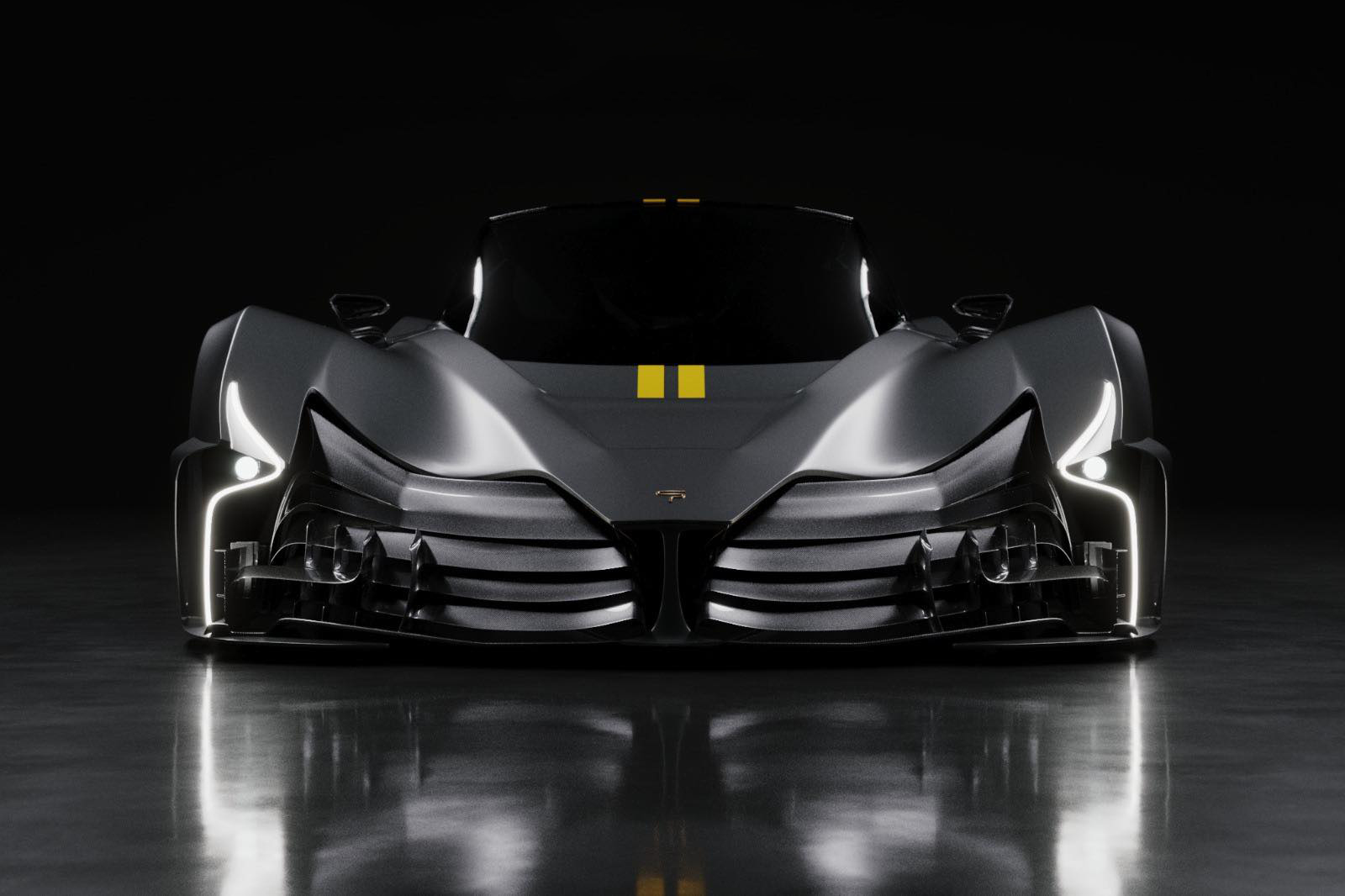

Chaos is an innovative Ultracar, a true foundation of reality that was created to fill the gap in appearance and user experience in the hypercar market. It is built exclusively by using Anadiaplasis, an innovative design and production method invented by Spyros Panopoulos and true exotic materials which ensure the extraordinary performance. The eerie and modern look, the led tech details of high aesthetics, the promising interior, the carefully designed aerodynamics combined with 5G technology, and the breathtaking numbers >530km/h, 3000hp, <1200kg, up to 14.000 rpm, prove that Chaos is the future.

AT FIRST CHAOS CAME TO BE.

THE FIRST 5G CAR

ESTIMATED PERFORMANCE

POWER

2000hp

TOP SPEED

>+500km/h (>+310mph)

POWER TO WEIGHT RATIO

2,05

DIMENSION

LENGTH

5.053mm (198.93in)

WIDTH

2.068mm (81.417in)

HEIGHT

1.121mm (44.133in)

WHEELBASE

2.854mm (112,362in)

WEIGHT

1.388kg (2839.55lb)

ACCELERATION

0-100 KM/H (0-62mph)

< 1,9sec

100-200km/h (62-124mph)

< 2,7sec

160-241km/h (100-150mph)

< 2,3sec

0-300kph (0-186,41mph)

< 7,9sec

0-402m (1/4mile)

< 8,1sec

POWER

3000hp

TOP SPEED

>+500km/h (>+310mph)

POWER TO WEIGHT RATIO

3,06

DIMENSION

LENGTH

5.053mm (198.93in)

WIDTH

2.068mm (81.417in)

HEIGHT

1.121mm (44.133in)

WHEELBASE

2.854mm (112,362in)

WEIGHT

1.272kg (2804.27lb)

ACCELERATION

0-100 KM/H (0-62mph)

< 1,55sec

100-200km/h (62-124mph)

< 1,7sec

160-241km/h (100-150mph)

< 1,4sec

0-300kph (0-186,41mph)

< 7,1sec

0-402m (1/4mile)

< 7,5sec

ENGINE

Type V10 90 degrees

Billet aluminum engine block 7 axis point milled.

Displacement: 3.955,8 cm3

Max power: 2.048,7hp (1527.7kw)

Max torque: 1.389,4Nm (1024.7ftlb)

Red line: 10.000 – 11.000rpm (depends on the final engine and fuel set up)

Mean piston Velocity: 27,1 m/s

Instantaneous piston Velocity: 32,5 m/s

Max. piston velocity: 43,83 m/s

Max. piston acceleration (@TDC): 60.892 m/s2

Max. piston acceleration (@TDC): 6.207,1 G’s

Instantaneous acceleration: 39.658 m/s2

Instantaneous acceleration: 4,042,6 G’s

Lubrification: Dry Sump

Type V10 90 degrees

3D printed Magnesium alloy engine block.

Displacement: 3.955,8 cm3

Max power: 3.064,7hp (2284.9kw)

Max torque: 1.983,5Nm (1462.9ftlb)

Red line: 11.800rpm – 12.200rpm (depends on the final engine and fuel setup)

Mean piston Velocity: 29,6 m/s

Instantaneous piston Velocity: 35,45 m/s

Max. piston velocity: 47,82 m/s

Max. piston acceleration (@TDC): 72.466 m/s2

Max. piston acceleration (@TDC): 7.386,9 G’s

Instantaneous acceleration: 47.196 m/s2

Instantaneous acceleration: 4.811,0 G’s

Lubrification: Dry Sump

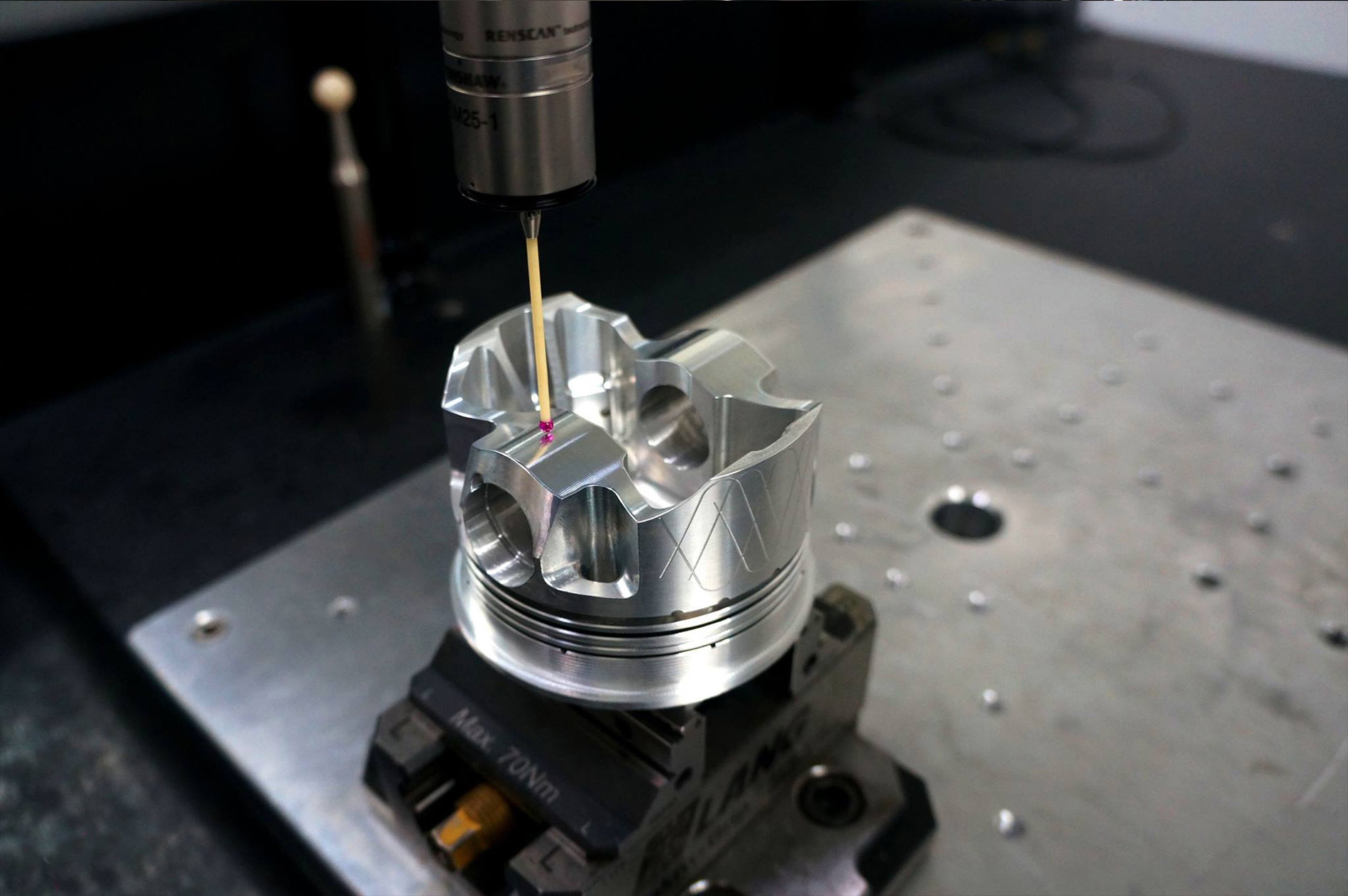

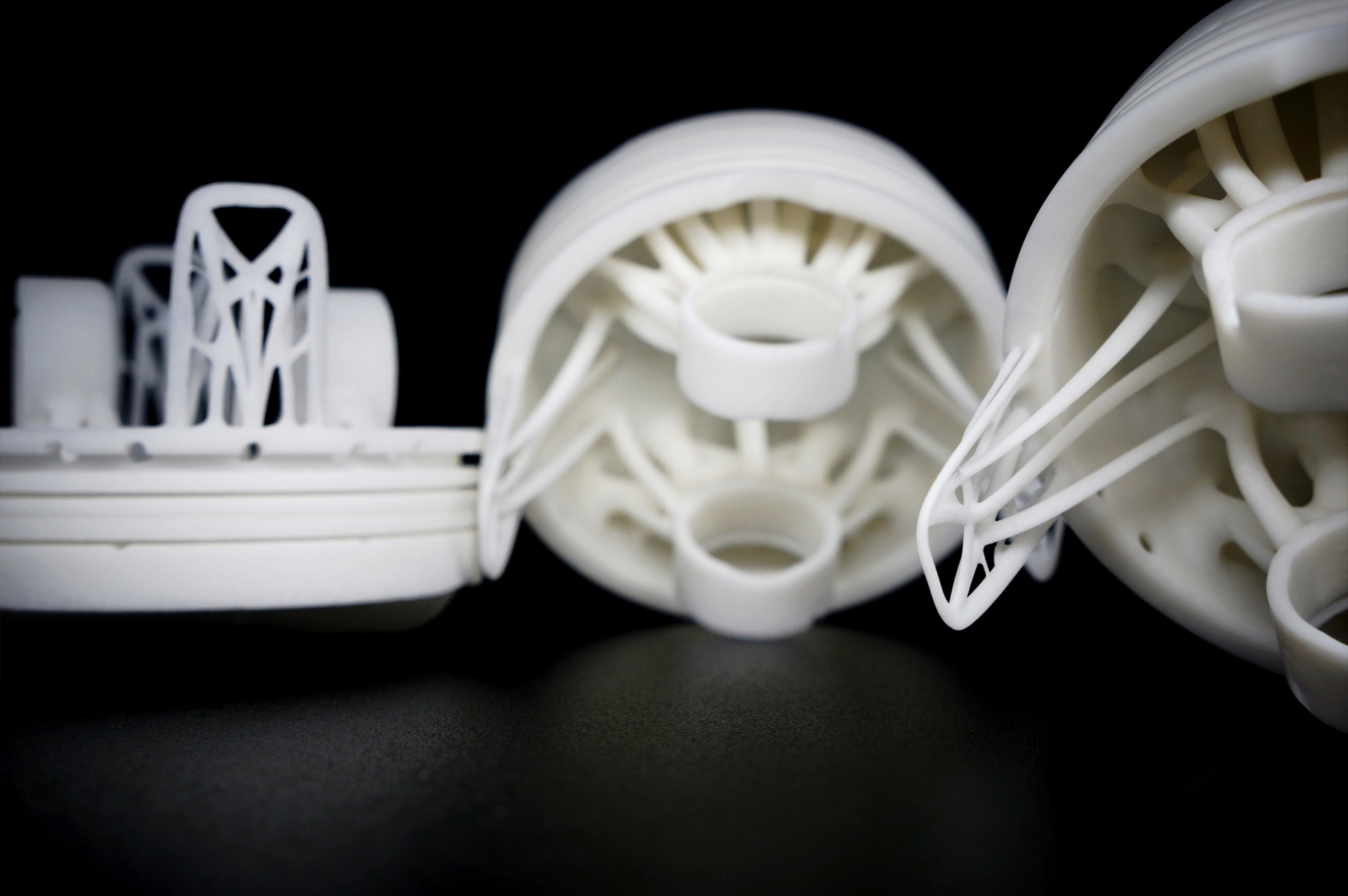

PISTONS

Billet 7 axis point milled X design billet Tennalumsuper alloy

Ultra-strength – Ultimate alloy (683Mpa yield strength), has the highest mechanical strength of all commercially available aluminum alloys (2.5 times stronger than 6061, and 35% stronger than 7075) and exceeds that of many steels. In fact, its yield strength is approaching that of pre-hardened (HRC 26-32) 41XX and 400 series stainless steels but at a third of the weight. In strength-to-weight ratio, Tennalum out performs nearly all other engineering alloys in existence (33% better strength-to-weight performance than 7075, and 28% better performance than 6Al-4V Grade 5 Titanium)

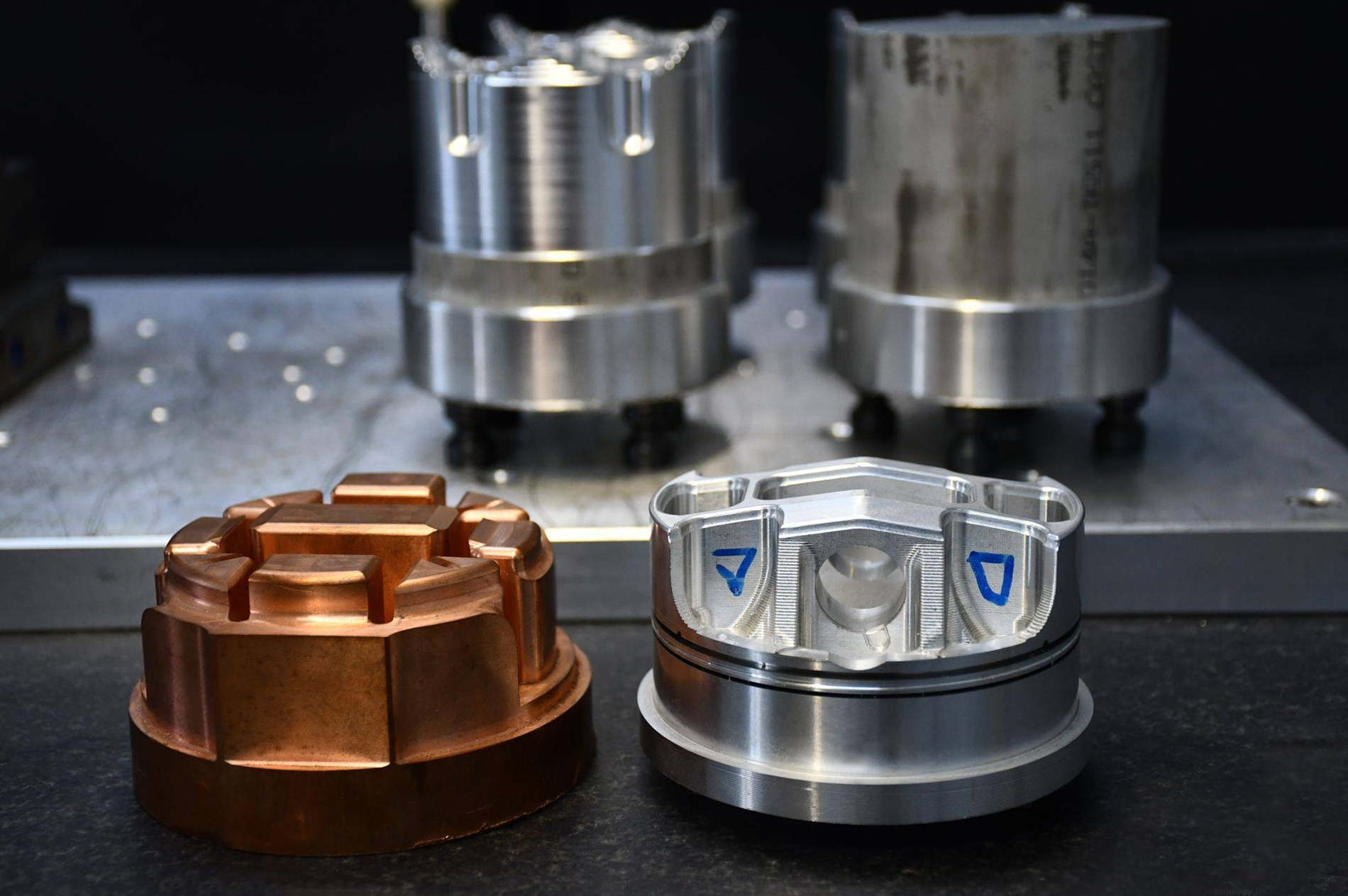

Tennalum super alloy, Sinker EDM

Sinker EDM technique uses an energized shaped electrode in a submerged bath of dielectric fluid to machine conductive metals and offers an efficient manufacturing method to produce complex part details that are difficult to machine by other methods, like 5 axis machines etc. Sinker spark erosion machines are fitted with an Intelligent Speed Power Generator (ISPG) which, using patented technologies, establishes new standards in surface quality, material removal and accuracy of form. Electrode wear is reduced in all machining operations, from roughing to finishing, with copper or graphite electrodes. Productivity shows an average increase of 30 percent, and can even reach 100 percent for pre-milled forms. Even in the presence of deep, narrow cavities, with poor flushing conditions, a 50 percent increase in erosion speed can be obtained with no increase in electrode wear. It appears that the more complex the piston design is, the more high quality of surface.

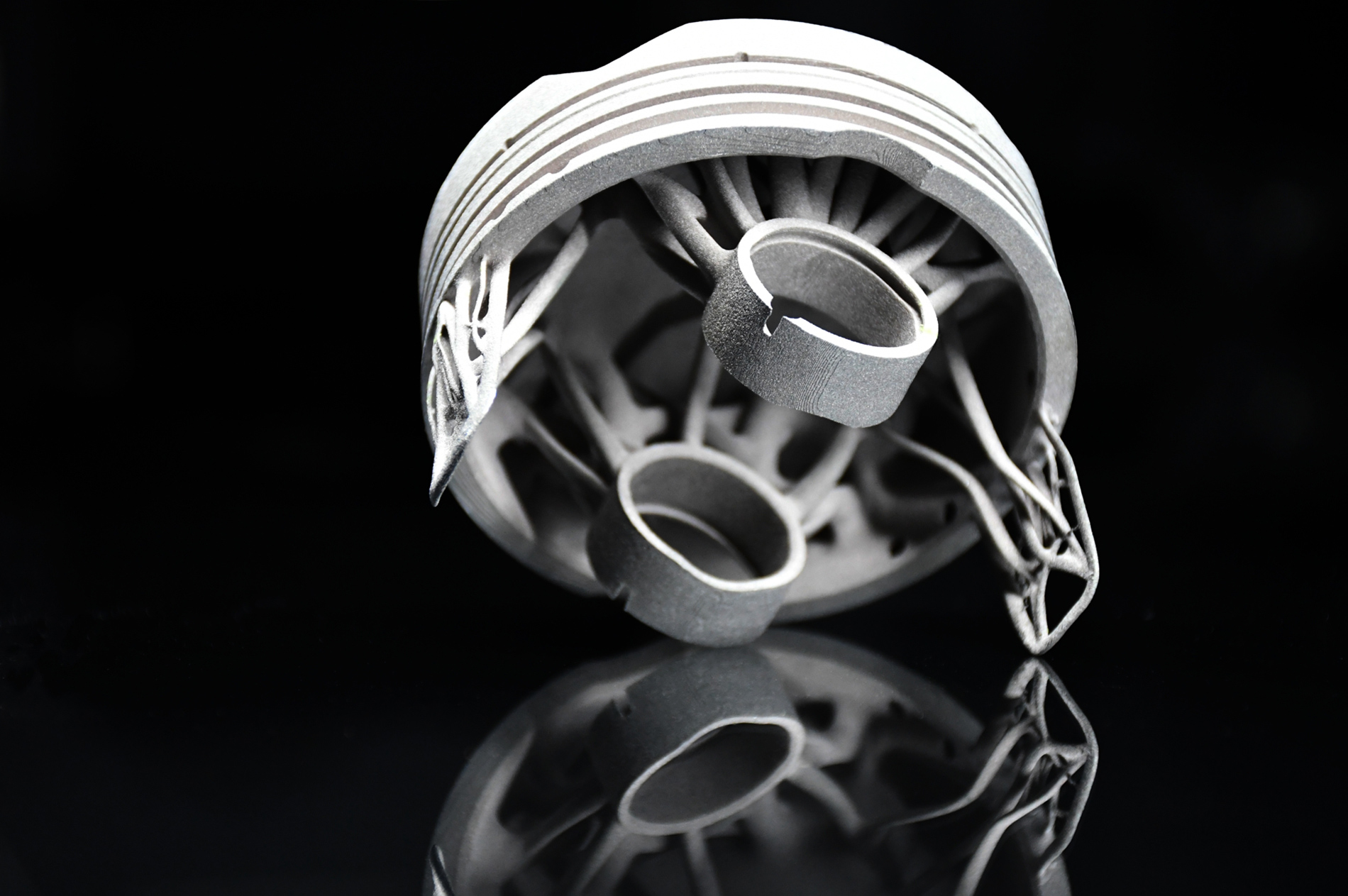

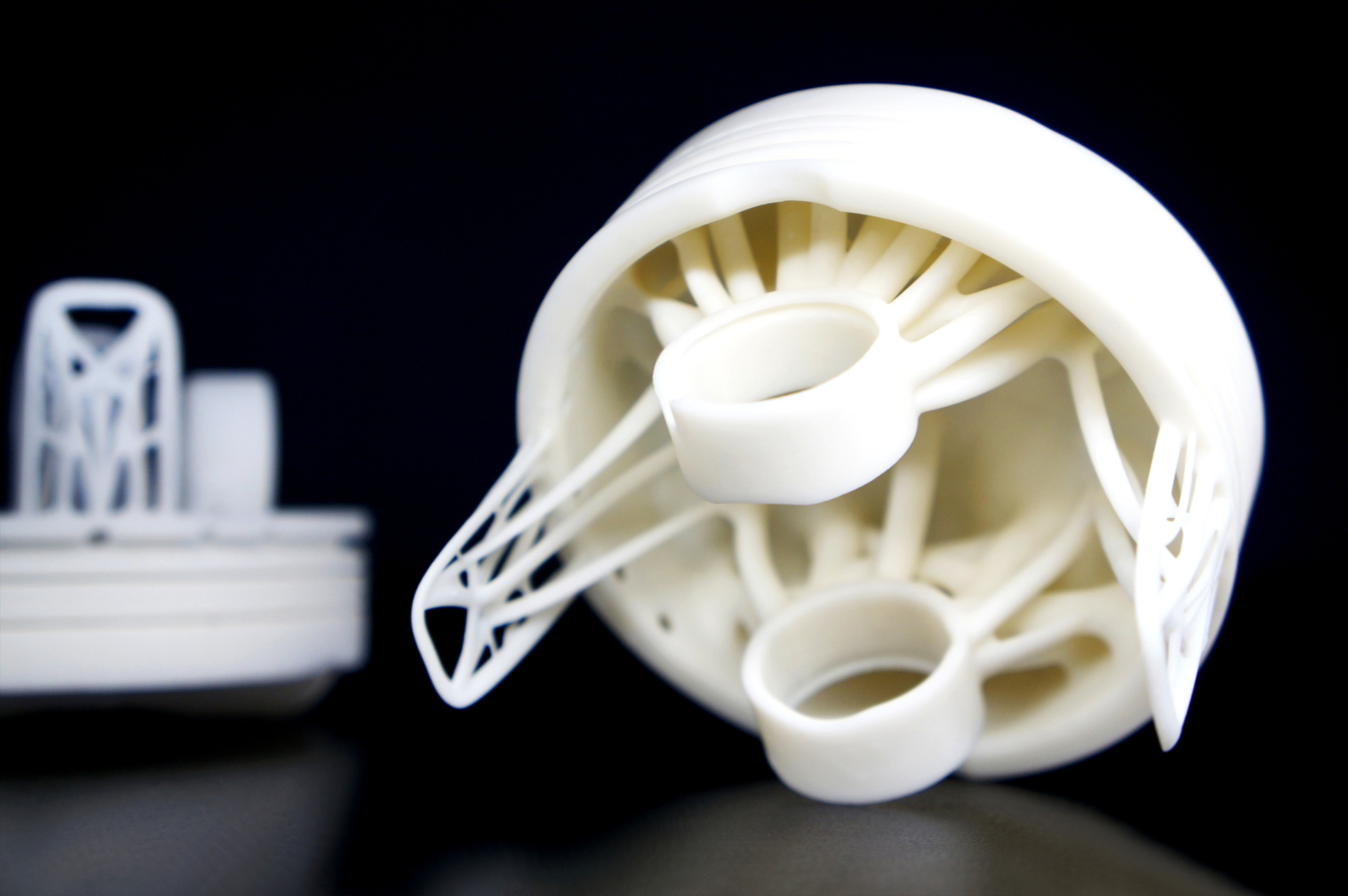

Titanium 3D printed Anadiaplasi

Stainless Tool Steel H13 3D printed Anadiaplasi (not recommended for this setup)

Billet 7 axis point milled X design billet Tennalumsuper alloy

Ultra-strength – Ultimate alloy (683Mpa yield strength), has the highest mechanical strength of all commercially available aluminum alloys (2.5 times stronger than 6061, and 35% stronger than 7075) and exceeds that of many steels. In fact, its yield strength is approaching that of pre-hardened (HRC 26-32) 41XX and 400 series stainless steels but at a third of the weight. In strength-to-weight ratio, Tennalum out performs nearly all other engineering alloys in existence (33% better strength-to-weight performance than 7075, and 28% better performance than 6Al-4V Grade 5 Titanium)

Tennalum super alloy, Sinker EDM

Sinker EDM technique uses an energized shaped electrode in a submerged bath of dielectric fluid to machine conductive metals and offers an efficient manufacturing method to produce complex part details that are difficult to machine by other methods, like 5 axis machines etc. Sinker spark erosion machines are fitted with an Intelligent Speed Power Generator (ISPG) which, using patented technologies, establishes new standards in surface quality, material removal and accuracy of form. Electrode wear is reduced in all machining operations, from roughing to finishing, with copper or graphite electrodes. Productivity shows an average increase of 30 percent, and can even reach 100 percent for pre-milled forms. Even in the presence of deep, narrow cavities, with poor flushing conditions, a 50 percent increase in erosion speed can be obtained with no increase in electrode wear. It appears that the more complex the piston design is, the more high quality of surface.

Titanium 3D printed Anadiaplasi

Stainless Tool Steel H13 3D printed Anadiaplasi (not recommended for this setup)

Ceramic 3D Nano printed Anadiaplasi zero friction

One of the best weight to compressive Strength ratio on earth, and thermal Conductivity. Can withstand temperatures over 1.500c (2.730F). We print it in NANO to achieve maximum accuracy on tolerances as can’t be machined after production.

Silicon Carbide 3D Nano printed Anadiaplasi

The ultimate compressive strength material of 3.900Mpa and Hardness of 2.800kg/mm2. Can withstand temperatures over 1.650c (3.000F). We print it in NANO to achieve maximum accuracy on tolerances as can’t be machined after production.